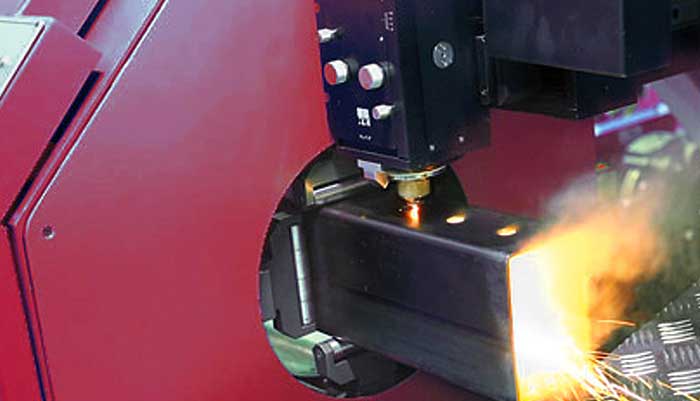

For XXL tube production, the machine was designed to maximize productivity. The machine's solid-state laser can be used to process tubes and profiles in many ways. It is compatible with many types of material and wall thicknesses.

You may have noticed that we havenít discussed cutting speed yet. It is possible to cut up to 500 inches per minute on a tube, but thatís not always realistic. In laser tube cutting, the real focus should be on how long it takes to load a tube, index it so itís in the right position for cutting, pierce and cut it, and unload the part. Itís more about part-processing time with laser tube cutting machines, not cutting speed.